In power electronics, IGBTs and MOSFETs are key semiconductor switches used to manage high voltage and current. Though they seem similar, each has unique traits that suit different applications. The right choice depends on circuit needs like voltage level, switching speed, efficiency, and cost.

What is a MOSFET?

A MOSFET is a transistor used to amplify or switch electronic signals by controlling gate voltage. The device manages the flow of current between the drain and source terminals, depending on the gate voltage applied. Its main benefits are fast switching speed and low conduction loss. These features make it ideal for low-voltage uses like DC-DC converters, chargers, and small devices.

Key features of MOSFETs:

- High switching speed

- Efficient in low-voltage applications (under 250V)

- Low gate drive power

- Better efficiency at high frequencies

- More suitable for light-load and portable devices

MOSFETs are preferred when the switching frequency is high because they switch on and off faster. This means they waste less energy during each transition, which is a major benefit for devices that turn on and off hundreds or thousands of times per second.

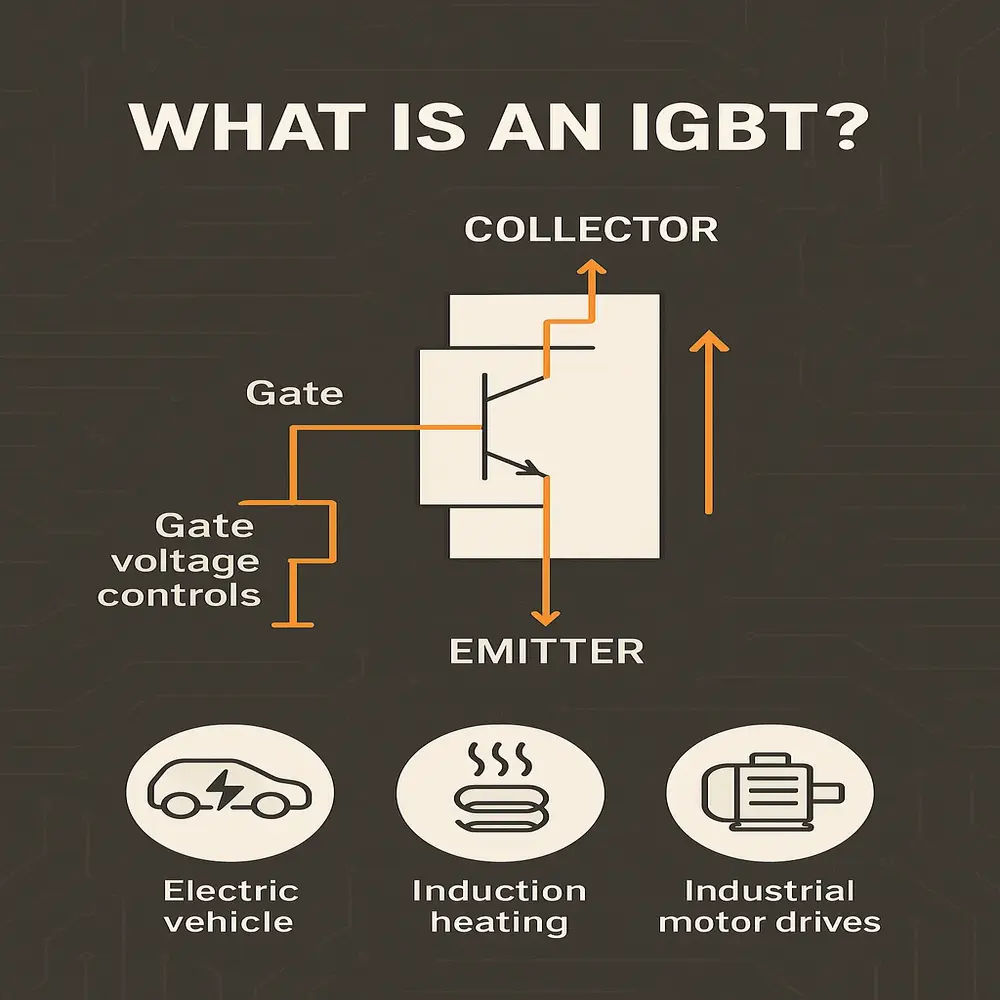

What is an IGBT?

IGBT stands for Insulated Gate Power Transistor. It merges the easy gate control of a MOSFET with the high-current handling and low saturation voltage benefits of a current-controlled junction transistor (BJT). IGBTs are usually chosen for high-power applications like electric vehicles, induction heating, and industrial motor drives.

Key features of IGBTs:

- Capable of handling higher voltages (typically above 400V)

- Better suited for medium to high-power applications

- Slower switching speed compared to MOSFETs

- Higher conduction losses at lower frequencies

- Often more rugged and durable

IGBTs are more robust when dealing with high-voltage loads, making them ideal in scenarios where rapid switching is not required, but a large amount of current or energy needs to be managed without the risk of breakdown.

Main Differences Between IGBT and MOSFET

To make things simpler, here’s a breakdown of the major differences between IGBTs and MOSFETs based on several performance aspects:

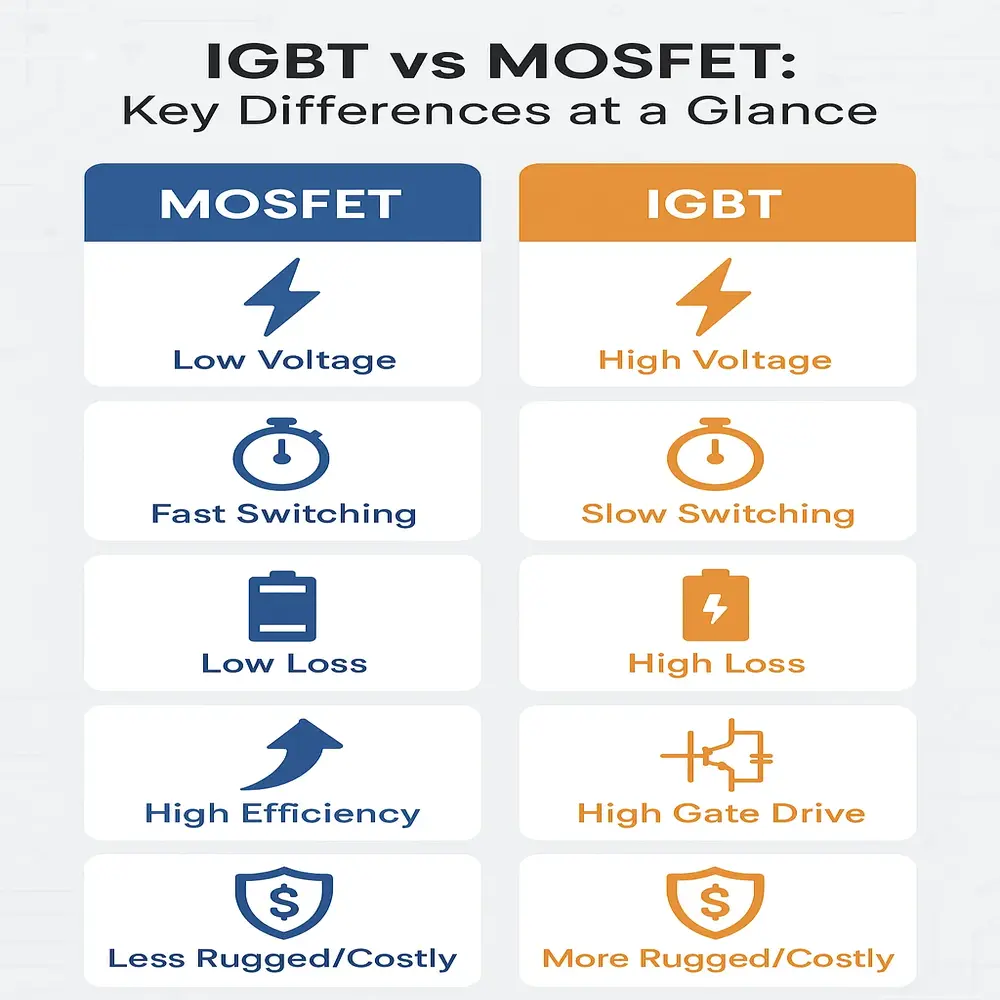

1. Voltage Range

- MOSFET: Best for low to moderate voltages (up to around 250V)

- IGBT: Best for higher voltages (400V and above)

If your circuit involves lower voltages, a MOSFET is likely more efficient. However, for high-voltage operations, an IGBT performs better and lasts longer.

2. Switching Speed

- MOSFET: Faster switching speeds, ideal for high-frequency applications

- IGBT: IGBTs operate at slower switching speeds, making them less suitable for applications that require very high-frequency performance.

For devices like computers or high-speed inverters, MOSFETs are a better pick. But for industrial uses where switching speed isn’t a top priority, IGBTs are strong candidates.

3. Power Loss

- MOSFET: Lower conduction loss but higher switching loss at high voltages

- IGBT: Lower switching loss but higher conduction loss at low frequencies

This means MOSFETs are more energy-efficient in quick on/off cycles, while IGBTs are better when the switch stays on longer.

4. Efficiency

- MOSFET: Better efficiency at high frequencies

- IGBT: More efficient at lower frequencies and high voltage levels

IGBTs lose efficiency in high-speed switching but perform well in steady, high-load environments.

5. Gate Drive Requirements

- MOSFET: Needs less gate drive power

- IGBT: Needs a bit more to turn on/off

Since gate control circuitry adds to system cost and complexity, MOSFETs are simpler to control electronically.

6. Ruggedness and Cost

- MOSFET: Cheaper for small-scale, low-voltage applications

- IGBT: More expensive but more durable under high-voltage

For budget-conscious designs involving small loads, MOSFETs are cost-effective. For mission-critical, high-load applications, the reliability of an IGBT justifies the cost.

Applications of MOSFETs

You’ll often see MOSFETs used in:

- Battery-powered electronics

- Low-voltage power supplies

- Switching regulators (DC-DC converters)

- LED drivers

- Power amplifiers

- Low-power motor drives

They are compact, easy to integrate, and well-suited for mobile and consumer electronics.

Applications of IGBTs

IGBTs are commonly found in:

- Electric cars and trains

- Industrial motor control systems

- Induction heaters

- Solar inverters

- Uninterruptible Power Supplies (UPS)

- Welders

These are typically situations where voltages are high and loads are heavy.

Which One Should You Use?

The decision in the IGBT vs MOSFET comparison ultimately depends on the specific needs of your project. Here’s a brief and helpful guide to assist you in making the right choice:

Use a MOSFET if:

- Your application involves voltage under 250V

- You need a high switching speed

- You’re designing a lightweight or portable device

- Power efficiency in fast switching is important

- Cost is a limiting factor

Use an IGBT if:

- Your application involves voltages over 400V

- You need to manage large power loads

- Switching speed isn’t critical

- The system needs to run continuously for long periods

- You need higher ruggedness and reliability

Technology Evolution and Trends

As power electronics evolve, the IGBT vs MOSFET landscape is shifting with the introduction of advanced materials like Silicon Carbide (SiC) and Gallium Nitride (GaN), which enhance performance and efficiency. These offer faster switching, better heat handling, and enhanced performance. Gallium Nitride (GaN) performs exceptionally well in high-frequency applications, whereas Silicon Carbide (SiC) enhances the performance of IGBTs in high-power environments.

However, for now, silicon-based IGBT vs MOSFET components continue to dominate industrial and consumer power electronics due to their balanced performance, wide availability, and cost-effectiveness.

Comparison Table

A side-by-side table makes your content easy to scan:

| Feature | MOSFET | IGBT |

| Voltage Range | Up to ~250V | 400V and above |

| Switching Speed | Very fast | Moderate |

| Frequency Range | Up to 1 MHz | Up to 20 kHz |

| Conduction Loss | Low at low voltage | Low at high voltage |

| Switching Loss | High at high voltage | Lower than MOSFET at high V |

| Gate Drive Power | Low | Moderate |

| Ruggedness | Less robust | More robust |

| Cost | Cheaper at low power | Higher but worth it at high power |

| Applications | Portable electronics, DC-DC | Motor drives, EVs, inverters |

Real-World Examples

This adds relatability to your blog.

- MOSFETs in use: Laptop power supply circuits, LED drivers, drone ESCs, smartphone chargers.

- IGBTs in use: EV traction inverters (e.g., Tesla’s earlier models), industrial VFDs (variable frequency drives), and high-power induction heating.

Final Thoughts

The choice between IGBT vs MOSFET depends entirely on the specific requirements of your application, such as voltage, speed, and power handling. MOSFETs work best in high-speed, low-voltage setups, while IGBTs handle high-voltage, high-power tasks. Understanding your system’s voltage, load, and switching needs helps you select the right device for optimal performance and cost efficiency.

Related Topic: How to Understand IGBT and MOSFET Differences?