Visual inspection systems are advanced technologies that automate the process of checking products for defects, ensuring quality and consistency. Used in industries like manufacturing, automotive, and pharmaceuticals, these systems leverage computer vision and AI to enhance efficiency. This article covers their components, applications, and implementation tips.

What Are Visual Inspection Systems?

Visual inspection systems use cameras, sensors, and software to analyze products for defects, dimensions, or compliance with standards. They replace manual inspections, offering speed, accuracy, and scalability for modern production lines.

These systems mimic the human visual process but with far greater precision and consistency. They can operate 24/7 without fatigue, helping companies maintain strict quality standards even at high production volumes. From small-scale factories to global assembly lines, visual inspection is becoming a key part of operational excellence.

Components of Visual Inspection Systems

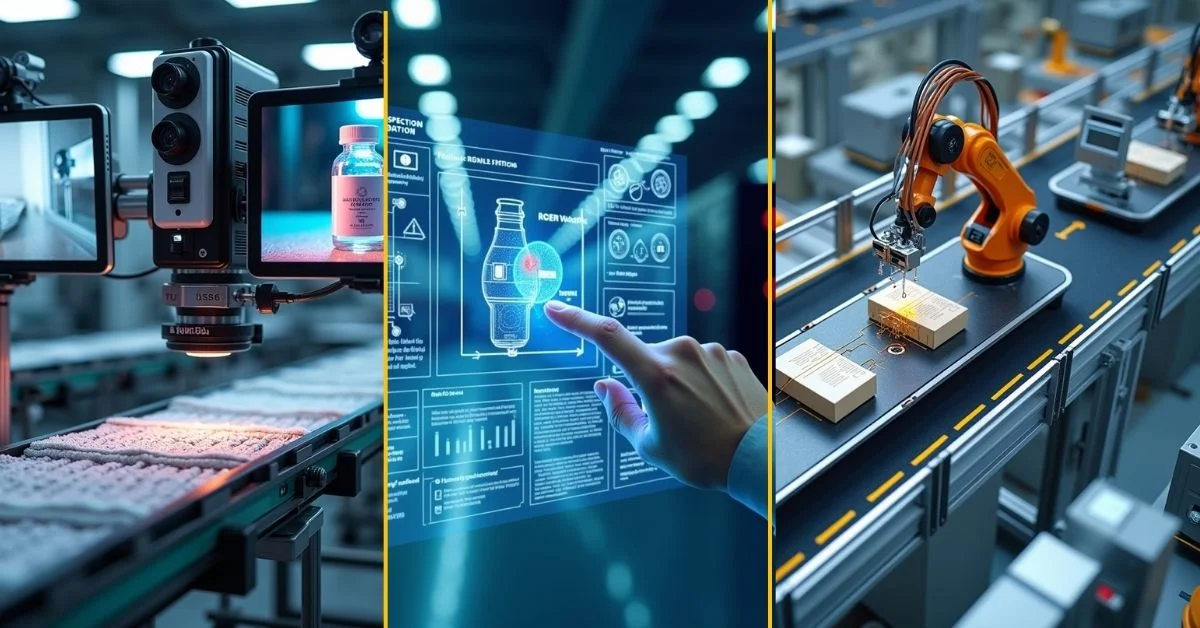

1. Cameras and Sensors

High-resolution cameras capture detailed images, while sensors detect specific attributes like color or texture. Multiple cameras may be used to view a product from different angles, and lighting systems can be adjusted to highlight specific features.

For instance, in pharmaceutical packaging, ultraviolet snsors might be used to check for invisible security markers on bottles, while in textiles, specialized lighting can reveal fiber inconsistencies.

2. Software and AI

AI algorithms process images to identify defects or anomalies, often using machine learning for accuracy. These algorithms can be trained to detect variations that would be difficult for human inspectors to notice, such as micro-cracks, minute color shifts, or incorrect font printing on labels.

Software can also log inspection data in real time, providing actionable insights and generating reports for compliance, traceability, and production optimization.

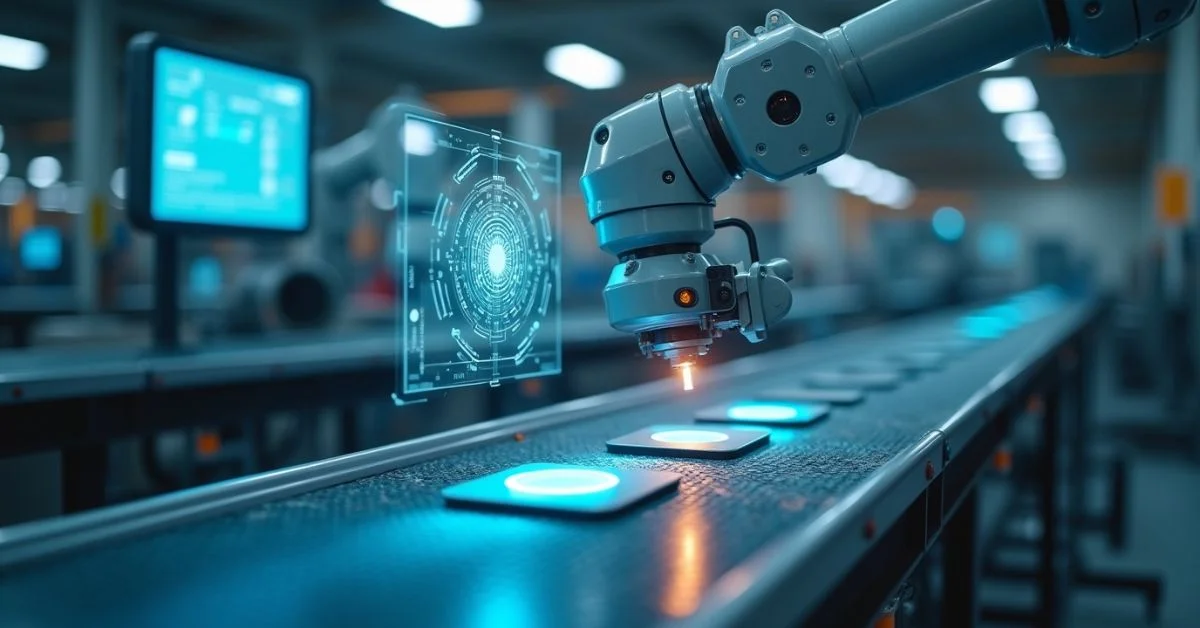

3. Integration Hardware

Conveyor belts or robotic arms integrate systems into production lines. Some setups may include actuators that remove defective items from the line or sort them based on inspection results.

Integration can also include programmable logic controllers (PLCs) that ensure seamless communication between machines and the visual inspection software.

Applications

Visual inspection systems find applications in various industries:

- Electronics: Inspect circuit boards for soldering defects, missing components, and alignment of microchips.

- Food Industry: Ensure packaging integrity, label accuracy, fill levels, and contamination detection.

- Automotive: Verify component alignment, surface finish, welding quality, and assembly accuracy.

- Pharmaceuticals: Confirm correct labeling, packaging seal integrity, and the presence of necessary inserts.

- Textiles: Identify weaving defects, dye inconsistencies, or incorrect stitching in garments.

- Logistics: Scan barcodes, track package damage, and validate labeling accuracy before dispatch.

Implementation Tips

Define Requirements

Identify specific inspection needs. This includes understanding what kinds of defects need detection, production speed, object size variations, lighting conditions, and resolution needs. A detailed requirement plan avoids overengineering and keeps the system cost-effective.

Choose Scalable Systems

Select systems that can grow with your business. Look for modular platforms that allow for hardware upgrades or software model retraining without needing a complete overhaul.

Scalability also means compatibility with future automation tools or expansion into multiple product lines.

Monitor Performance

Regularly evaluate system accuracy and update models. Even AI-based systems may require retraining if product designs or materials change. Keep logs of false positives and negatives to fine-tune performance over time.

It’s also important to schedule calibration and maintenance checks to ensure optimal imaging quality and system responsiveness.

Challenges

High costs and integration complexity can be barriers. Pilot projects can help test systems before full deployment.

Some challenges include:

- Environmental conditions: Poor lighting or vibrations can affect accuracy.

- Data handling: Managing the large volumes of image data and reports.

- Employee training: Staff must understand how to operate, maintain, and interpret system outputs.

- Downtime risks: Malfunctions or poor integration can interrupt production.

However, with proper planning, support from solution providers, and trial runs, these challenges can be mitigated.

Conclusion

Visual inspection systems are essential for modern quality control. By adopting these technologies, businesses can improve efficiency and product quality. Start exploring solutions to enhance your operations.

With growing competition and tightening quality regulations, companies that integrate visual inspection systems gain a significant edge in reliability, compliance, and customer satisfaction. Whether you’re a small manufacturer or a global enterprise, these systems represent a strategic investment in quality, consistency, and innovation.