To make TQM work, companies use several helpful tools and techniques. These tools are simple but powerful. They help to understand problems, reduce waste, improve efficiency, and increase customer satisfaction.

The Role of TQM Tools in Decision Making

One of the most powerful benefits of using TQM tools is better data based decision making. Instead of guessing why defects happen or relying on assumptions, TQM encourages teams to analyze patterns, measure performance, and choose solutions that are backed by real evidence.

For example, control charts help managers monitor process stability over time. Pareto charts point out which few problems cause the most trouble. These tools reduce emotional bias and help create a culture of fairness, logic, and fact driven action.

How TQM Tools Support Team Collaboration?

TQM supports collaboration by using tools like flowcharts and cause-and-effect diagrams to help teams visualize problems and share ideas. Involving all levels from workers to managers leads to better solutions, stronger ownership, and greater trust across the team.

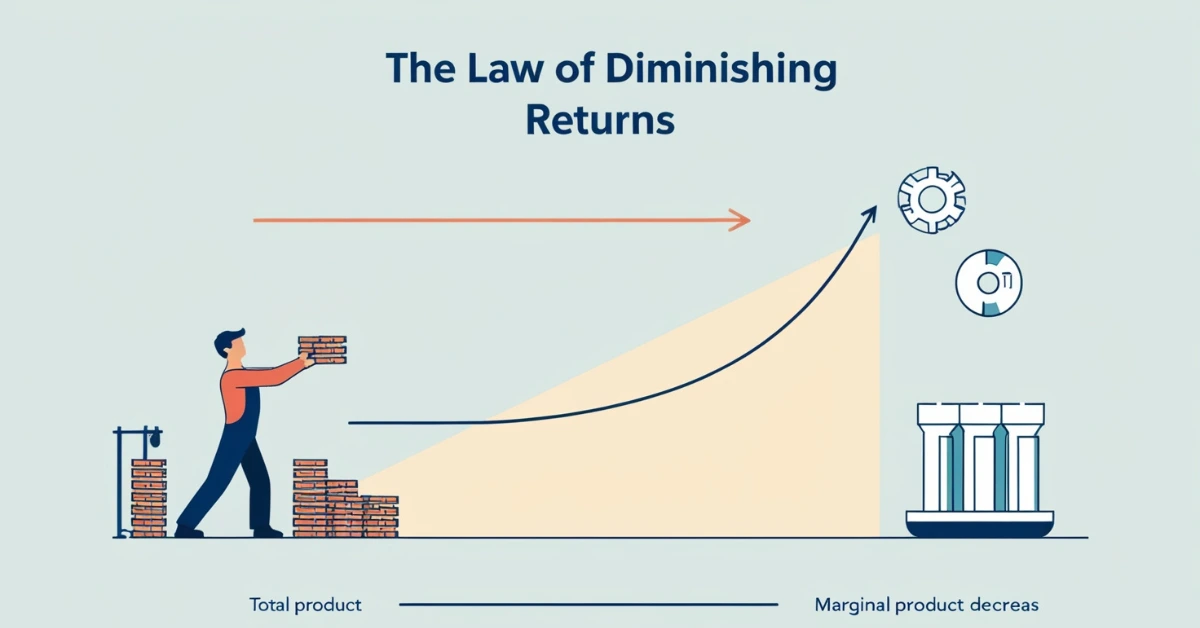

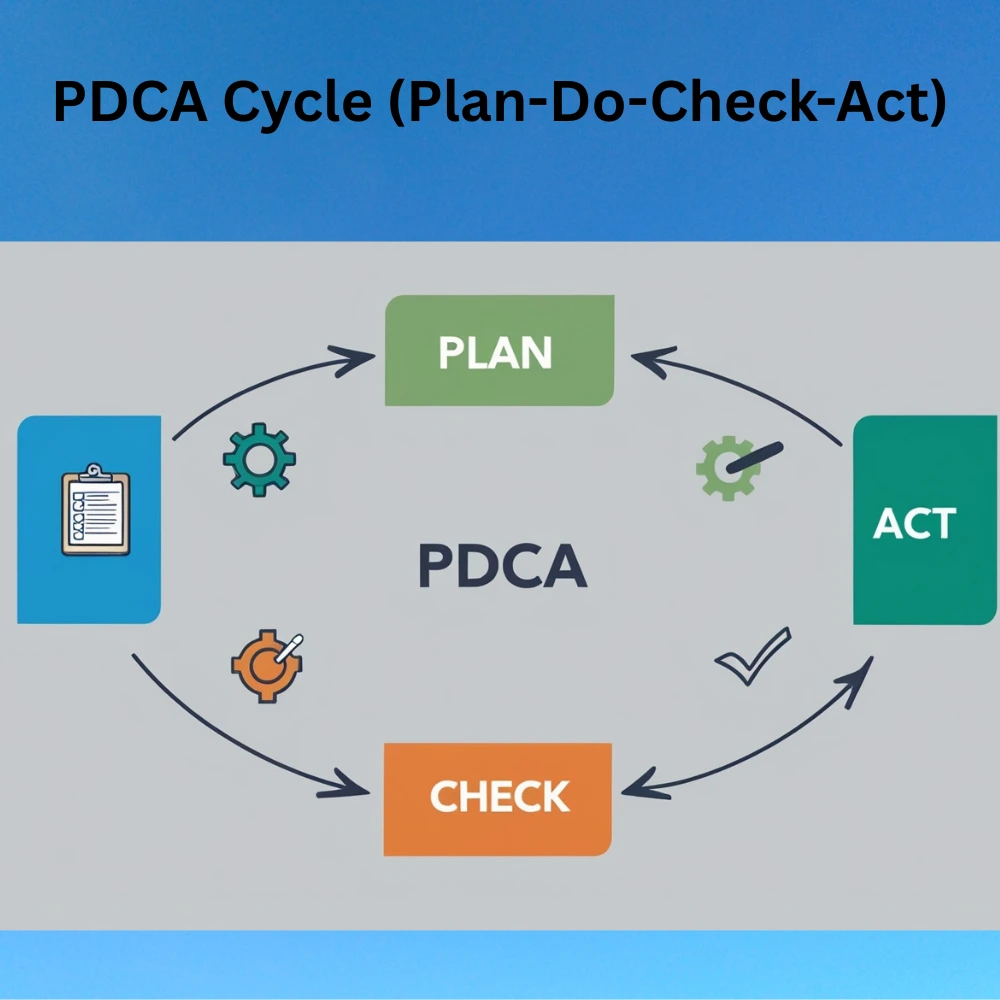

TQM Tool 1: PDCA Cycle (Plan-Do-Check-Act)

The PDCA Cycle, also called the Deming Cycle, is a core tool in Total Quality Management. It helps solve problems and improve processes continuously.

- Plan: Identify the problem and make a plan

- Do: Test the plan in a small trial

- Check: Measure and evaluate the results

- Act: Apply the solution broadly if successful

The PDCA cycle is simple, effective and widely used in quality focused companies.

TQM TOOL 2: The 7 Basic Quality Tools in TQM

These are simple tools that help solve most quality problems. They are often used in combination to make better decisions.

- Cause and Effect Diagram: This tool helps find the root cause of a problem. The “head” of the fish shows the problem, and the “bones” show possible causes grouped into categories like people, process, materials, or equipment.

- Flowchart: A flowchart shows the steps in a process. It helps teams understand how a process works, spot delays, and find areas for improvement.

- Check Sheet: A check sheet is a simple form used to collect data. For example, it can track how often a problem occurs each day or which type of defect appears most often.

- Histogram: This is a type of bar chart that shows how often each value appears. It helps you understand patterns in data.

- Pareto Chart: This chart is based on the 80/20 rule, which means that 80% of problems come from 20% of causes. The Pareto Chart helps identify those few causes that create most of the issues.

- Scatter Diagram: This shows how two variables are related. For example, it might show that the number of defects increases with machine speed.

- Control Chart: Control charts track how a process changes over time. It helps identify when something is going wrong so it can be fixed early.

TQM Technique 3: Benchmarking in Total Quality Management

Benchmarking is a powerful TQM technique used to learn from the best. It involves comparing your processes or performance to other companies to identify gaps and improve.

Types of benchmarking:

- Internal: Between departments

- Competitive: Against industry rivals

- Functional: With top performers in different industries

Benchmarking encourages innovation and high-performance culture.

TQM Tool 4: The 5 Whys Method for Root Cause Discovery

In Total Quality Management, finding the real cause of a problem is essential. The 5 Whys technique is a simple way to dig deep by asking “why?” repeatedly until the root is revealed.

Example:

- Why did the shipment delay? Delivery truck was late.

- Why? Traffic jam.

- Why? Driver took wrong route.

- Why? GPS wasn’t updated.

- Why? No routine GPS maintenance.

Solution: Schedule regular GPS updates.

TQM Technique 5: Kaizen for Continuous Quality Improvement

Kaizen means “change for better” and is at the heart of Total Quality Management. It focuses on making small, consistent improvements every day with involvement from all team members.

Benefits of Kaizen in TQM:

- Builds teamwork

- Reduces waste

- Improves productivity

- Encourages employee suggestions

Even small changes add up over time, making Kaizen a powerful TQM tool.

TQM Technique 6: Six Sigma for Process Perfection

Six Sigma is often used alongside TQM to reduce variation and defects. It uses the DMAIC framework:

- Define: State the problem

- Measure: Collect data

- Analyze: Identify the root causes

- Improve: Create and test solutions

- Control: Maintain improvements

Six Sigma is data driven and is especially effective in industries like manufacturing and healthcare.

TQM Tool 7: The 5S Method for Workplace Organization

The 5S Method is a simple but powerful technique in Total Quality Management for keeping the workplace neat and efficient:

- Sort: Remove unnecessary items

- Set in Order: Organize things logically

- Shine: Clean regularly

- Standardize: Create uniform practices

- Sustain: Maintain these habits daily

A clean, organized environment improves safety, morale, and speed.

TQM Tool 8: Total Productive Maintenance (TPM)

In TQM, equipment must be reliable. Total Productive Maintenance aims to reduce machine breakdowns and defects by involving operators in routine care.

TPM focuses on:

- No unplanned downtime

- Higher machine efficiency

- Better product quality

- Fewer accidents

It empowers workers to maintain their machines and avoid bigger problems.

TQM Tool 9: Quality Function Deployment (QFD)

QFD, also called the House of Quality, is a planning tool in TQM that turns customer needs into product features.

For instance, if customers want a lightweight, long lasting mobile phone, QFD helps ensure those features are prioritized during design and production.

QFD aligns customer expectations with technical solutions.

TQM Technique 10: Root Cause Analysis (RCA)

Root Cause Analysis is a structured method in Total Quality Management used when recurring issues appear. It goes beyond symptoms to uncover the underlying cause.

Often combined with:

- Fishbone Diagrams

- Flowcharts

- 5 Whys

RCA helps eliminate problems permanently, not just temporarily.

Digital Tools for TQM Implementation

Modern businesses are using software and apps to make TQM easier to implement. Digital TQM tools allow teams to:

- Create real time dashboards

- Monitor live process data

- Share reports across departments

- Automate quality checks and alerts

Popular software platforms like Minitab (for Six Sigma), Lucidchart (for process mapping), and Trello or Asana (for team collaboration) can complement traditional TQM methods. These tools improve speed, clarity and communication also important pillars of quality management in today’s digital world.

Conclusion

Total Quality Management (TQM) is a practical, people-centered approach focused on continuous improvement across all areas of a business. By applying proven tools and techniques, organizations can improve quality, reduce costs, engage employees, and build lasting customer trust. From simple checklists to full-scale Six Sigma programs, daily use of TQM methods supports long-term success.