Power Take-Off (PTO) shafts are crucial parts of many pieces of equipment, particularly in industrial and agricultural contexts. They transmit mechanical energy from an engine or tractor to a separate machine or an attached tool. This guide provides an in-depth look at PTO shafts, their types, safety considerations, maintenance practices, and applications

What is a PTO Shaft?

The mechanical part that moves power from a tractor or engine to another piece of machinery, like a mower, baler, or pump, is called a PTO (Power Take-Off) shaft. It enables the tractor’s power to be used by machines without their own engines. Depending on the needs of the machinery, PTO shafts are often found at the back of tractors and rotate at conventional rates of 540 or 1,000 revolutions per minute (RPM). These shafts are crucial to farming since they effectively power a variety of instruments and attachments. Because PTO shafts rotate at high speeds and can be dangerous if not used and maintained properly, they are essential for both performance and safety.

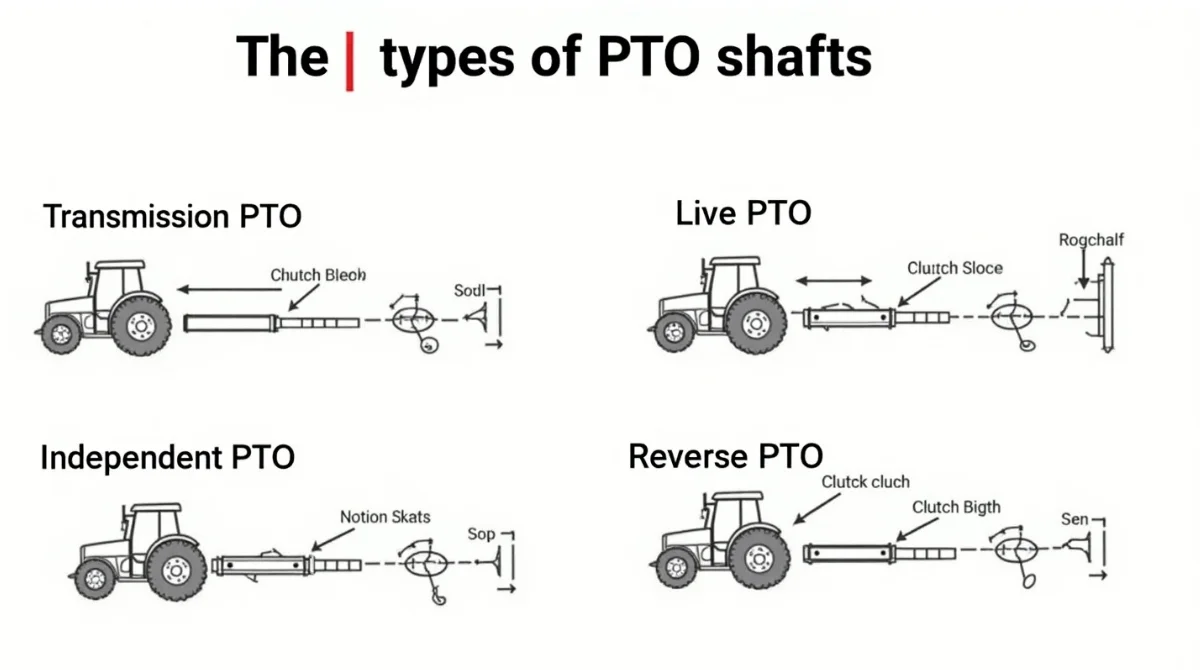

Types of PTO Shafts

There are several varieties of PTO shafts, and each is designed to serve a particular function based on how the tractor and equipment must cooperate. Let’s examine the four primary categories in simple terms:

1. Transmission PTO

This kind attaches straight to the tractor’s gears. This indicates that the PTO only operates when the tractor is in motion. Therefore, the PTO also stops when you engage the clutch or stop the tractor. It’s straightforward and adequate for easy tasks, but it doesn’t offer you much control.

2. Live PTO

The clutch on this model is two-step. The tractor wheels are controlled by one component, and the PTO is controlled by another. This implies that you can turn off the tractor without turning off the equipment you’re using, such as a mower. This makes it easier for you to work efficiently, particularly in confined spaces or when you need to slow down without stopping the machinery.

3. Independent PTO

You have complete freedom with this one. Even while the tractor is not moving, you can switch the PTO on or off whenever you choose. It is independent of the tractor’s gears and clutch. Because it improves equipment control, it is very practical and frequently found on contemporary tractors.

4. Reverse PTO

The shaft can spin backwards with this particular model. Although not present on all tractors, it is quite useful in the event that a tiller or other piece of equipment becomes stuck. You can safely remove the jam by spinning it the other way using reverse PTO.

Components of a PTO Shaft

Although a PTO (Power Take-Off) shaft may appear to be a straightforward spinning rod, it is actually composed of multiple critical components, each of which is essential to its operation and safety. Let’s summarize these key elements in simple terms:

1. Shaft

This is where the PTO is centered. It is the lengthy, rotating metal tube that transfers power from the tractor to the device you are operating, such as a sprayer or a lawnmower. It is the real energy transfer that powers your machinery.

2. Universal Joints

These components are located at both ends of the shaft and are also known as U-joints. They allow the PTO to revolve smoothly even when it moves at different angles. This is crucial since it’s rare for the tractor and the equipment you’re using to line up exactly. The shaft has the flexibility to continue operating even when the machine travels up or down thanks to these joints.

3. Safety Guards

These are metal or plastic covers that cover the rotating shaft for protection. Their primary responsibility is to keep you safe by keeping you away from the moving parts. Without these barriers, it may be extremely dangerous for hands, clothing, or tools to become entangled in the shaft. Safety guards are therefore essential.

4. Slip Clutches or Shear Pins

These are coverings made of metal or plastic that cover the rotating shaft for protection. Their primary responsibility is to protect you from contact with the moving parts. It can be extremely dangerous for hands, clothing, or tools to become entangled in the shaft without these barriers. Therefore, safety guards are essential.

These parts work together to support the PTO shaft’s safe and effective operation. Every component, from safety features to spinning power, is important to ensuring that everything functions properly and without mishaps.

Safety Considerations for Using PTO Shafts

Although PTO shafts are strong instruments, their use can make them quite hazardous. The shaft rotates at tremendous speeds and joins heavy machinery, so even a small mistake could cause serious damage.Safety should therefore always come first. The following important safety advice is presented in straightforward language:

1. Always Use Safety Guards

The rotating components of PTO shafts are covered by guards or shields. You are protected by these guards. Verify that they are never missing or broken and are always present. These safety covers assist keep you or your clothing from becoming caught, so never operate a PTO shaft without them.

2. Wear Appropriate Clothing

Untied hair, lengthy jewelry, and loose clothing can all be readily tangled in a rotating PTO shaft. In a matter of seconds, this might result in serious injury. Before operating any equipment that employs a PTO shaft, always wear fitted clothing, take off jewelry, and tie back long hair.

3. Disengage PTO Before Maintenanc

Always turn off the tractor’s engine and ensure the PTO is fully disengaged before inspecting, cleaning, or repairing any parts of the PTO or the machinery it powers. Don’t assume that just because the engine is silent, something is “off” By taking this easy step, accidents and unexpected movement can be avoided.

4. Stay Clear of Rotating Shafts

A PTO shaft should never be touched, stepped on, or lean across while rotating. A revolving shaft can instantly capture garments or limbs, even if it appears innocuous or slow. When the PTO is operating, always maintain a safe distance.

To put it briefly, PTO shafts are useful and effective, but they require deference. In addition to keeping you safe, following these safety guidelines guarantees that the equipment will function better and last longer. Serious incidents can be avoided tomorrow by exercising caution today.

Maintenance Practices

Maintaining the condition of your PTO shaft is important for more reasons than only extending its lifespan; it also ensures your safety and proper operation of your machine. If you follow a few straightforward procedures, regular maintenance is simple. Let’s examine what you ought to do:

1. Inspect Regularly

Examine the PTO shaft as soon as possible before and after use.Check for rust, bends, cracks, and any loose or damaged parts. Verify that all joints and safety guards are in place as well.Early detection of minor problems helps avert larger ones later on, such as catastrophic accidents.

2. Lubricate Moving Parts

Universal joints and other moving parts on PTO shafts must remain flexible and smooth. Grease these joints as well as any additional locations the manufacturer suggests. This makes everything spin more smoothly and silently by lowering wear and friction. Lubrication is essential for good operation, therefore don’t omit this step.

3. Replace Damaged Parts

Replace any worn-out, cracked, or bent parts as soon as you notice them. Safety hazards or malfunctions can result from even minor damageIt is never advisable to repair or force a damaged shaft to operate. Your machine will operate securely and effectively if you just use functional parts.

4. Store Properly

When not in use, don’t just leave the PTO shaft outside or toss it in the back of the shed. Store it somewhere dry and clean, away from physical harm, rain, and dirt. This keeps the shaft ready for the next task and helps stop rust.

Applications of PTO Shafts

Because of their extreme versatility, PTO (Power Take-Off) shafts are employed for a variety of activities in a broad range of sectors. They are crucial in many applications because of their capacity to distribute power from an engine or tractor to different devices. The following industries use PTO shafts:

1. Agriculture

PTO shafts are essential for powering a variety of farming tools. For instance, they run sprayers, tillers, balers, and mowers. Since these tools lack internal engines, they must be powered by the PTO shaft in order to perform operations like field mowing, hay baling, soil tilling, and fertilizer or pesticide spraying. Tractors can power many pieces of equipment thanks to the PTO, which greatly simplifies these tasks.

2. Construction

In the construction industry, PTO shafts are used to power equipment like cement mixers and pumps.They attach to large equipment and supply the mechanical power required to run devices like water pumps on building sites, hydraulic lifts, and concrete mixers. This makes it easier to complete tasks and allocate resources efficiently on large projects.

3. Emergency Services

Emergency vehicles like fire trucks and rescue vehicles also employ PTO shafts. These shafts support the operation of vital machinery like hydraulic tools and generators. For instance, the PTO shaft connects the engine of the fire truck to a hydraulic rescue tool (such as the Jaws of Life) in order to supply the required power. It’s essential to making sure these cars can function in an emergency.

4. Commercial Vehicles

Commercial trucks also employ PTO shafts to power a variety of machinery, such as cranes and vacuum systems. For example, PTO shafts power the vacuum pump in trucks equipped with vacuum systems for cleaning or suctioning debris. In a similar vein, PTO shafts supply the hydraulic power required for lifting operations in cranes on trucks or trailers that must raise and move big objects.

PTO shafts are a crucial component of machinery in each of these industries, providing dependable power transmission for a range of applications, from construction and farming to emergency services and commercial applications.

Conclusion

Anyone operating machinery that relies on PTO shafts must be aware of their types, functions, safety precautions, and upkeep. Operators can select the best PTO shaft type for a given operation by being aware of the many varieties, including transmission, live, independent, and reverse PTO. Accidents can be avoided by putting safety procedures into place, such as employing guards, dressing appropriately, and avoiding rotating parts. The longevity of the PTO shaft and the best possible equipment performance are guaranteed by routine maintenance, which includes lubrication, inspection, and part replacement. In addition to increasing productivity, proper handling and maintenance safeguard operators and guarantee years of safe and effective machinery operation.