Finite Element Analysis (FEA) is a powerful tool that helps engineers and designers understand how objects behave under various conditions. Whether it’s a bridge enduring heavy traffic, a car during a crash, or a smartphone experiencing heat, FEA allows for virtual testing and improvement of designs before they’re built.

What Is Finite Element Analysis?

Imagine trying to predict how a complex object like a car frame will react to stress. Instead of analyzing the entire structure at once, FEA breaks it down into smaller, manageable pieces called “elements.” By studying each element individually and then combining the results, engineers can get a comprehensive understanding of the whole structure’s behavior.

How Does FEA Work?

FEA follows a systematic process:

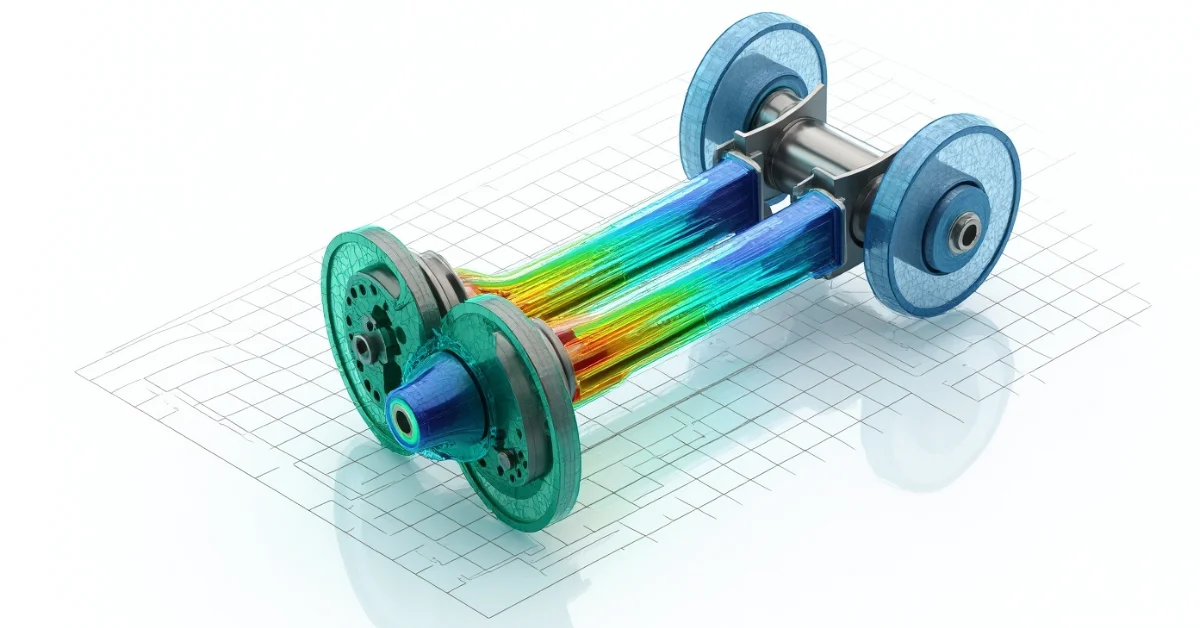

- Pre-processing: The object is divided into a mesh of elements. Material properties and boundary conditions (like forces or supports) are assigned.

- Solving: Mathematical equations are applied to each element to simulate physical behaviors such as stress, heat, or vibration.

- Post-processing: The results are compiled and visualized, often using color-coded diagrams to show areas of high stress or deformation.

Why Use FEA?

FEA offers several advantages:

- Cost Efficiency: By simulating tests virtually, companies can reduce the need for physical prototypes, saving time and resources.

- Improved Safety: Potential issues can be identified and addressed before production, enhancing the safety of the final product.

- Design Optimization: Engineers can experiment with different designs and materials to find the most effective solution.

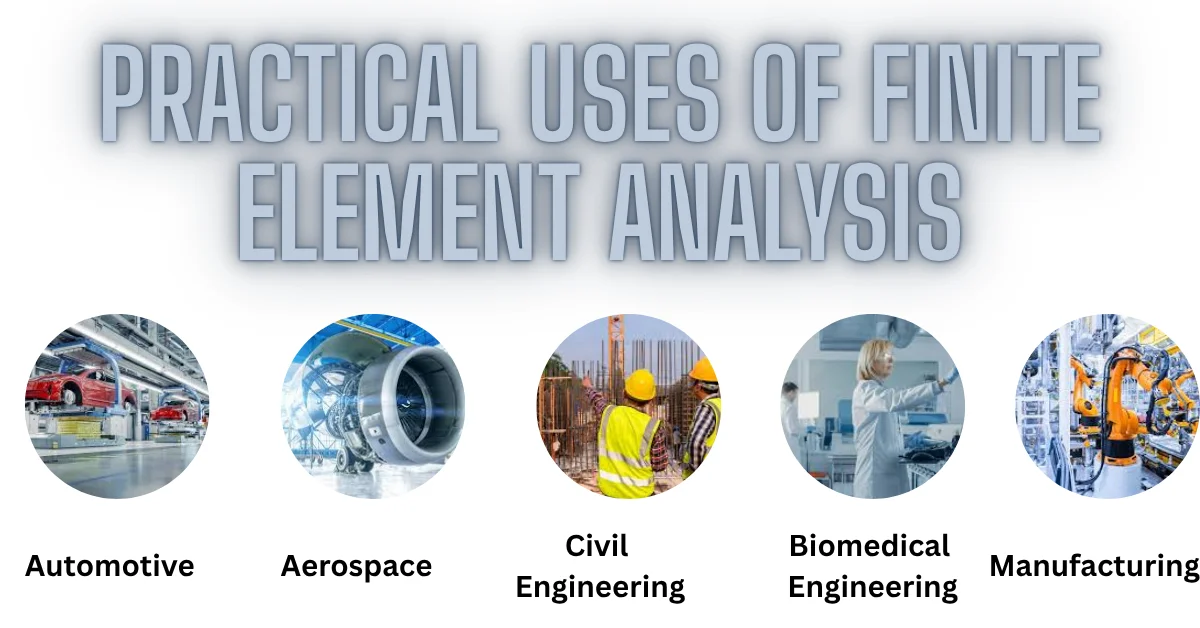

Applications

FEA is utilized across various industries:

- Automotive: Assessing crashworthiness, optimizing components for weight and strength.

- Aerospace: Simulating performance under extreme flight conditions.

- Civil Engineering: Evaluating the integrity of structures like bridges and buildings.

- Biomedical Engineering: Designing medical implants and prosthetics for optimal functionality.

- Manufacturing: Improving processes like casting and welding to enhance product quality.

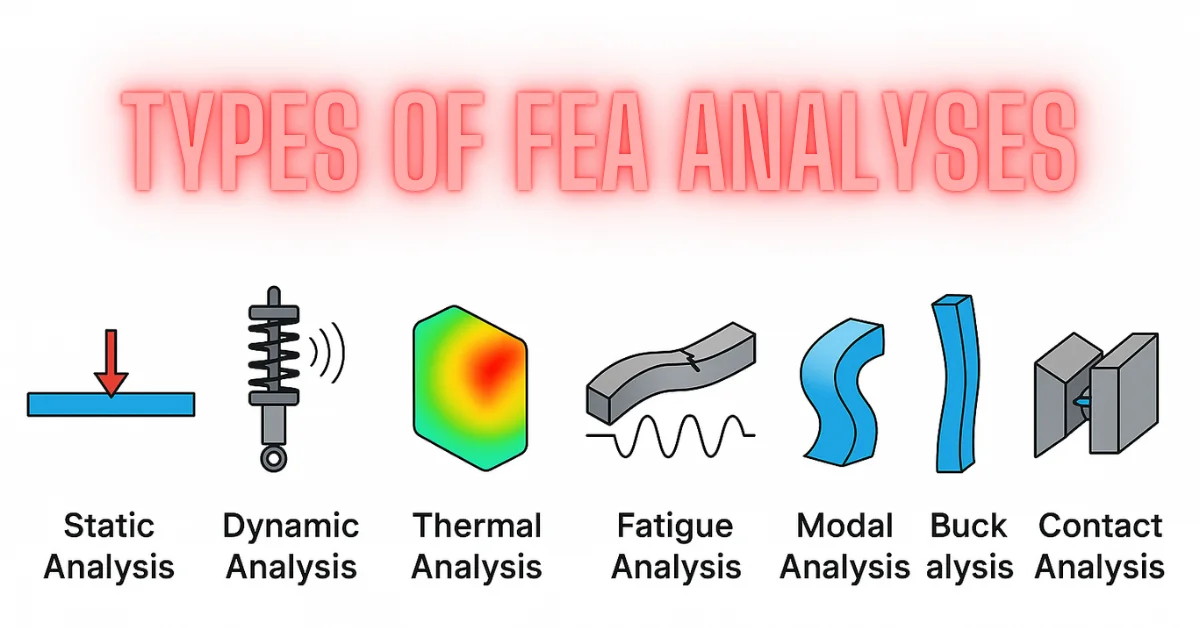

Types of FEA Analyses

Depending on the objective, different types of analyses are conducted:

- Static Analysis: Evaluates structures under constant loads.

- Dynamic Analysis: Assesses response to time-varying loads.

- Thermal Analysis: Analyzes heat transfer and temperature distribution.

- Fatigue Analysis: Predicts failure points under repeated loading.

- Modal Analysis: Determines natural frequencies and vibration modes.

- Buckling Analysis: Studies stability under compressive loads.

- Contact Analysis: Investigates interactions between contacting bodies.

The Importance of Meshing

Meshing is the process of dividing the object into elements. The quality of the mesh affects the accuracy of the analysis. A finer mesh provides more detailed results but requires more computational resources.

Real-World Example

Consider designing a new smartphone. Using FEA, engineers can simulate how the phone will react to drops, heat from prolonged use, and pressure from being in a pocket. By identifying potential weak points, they can reinforce specific areas, choose better materials, or adjust the design to enhance durability.

Tools and Software for FEA

Many companies use special FEA software tools. Some popular ones include:

- ANSYS

- Abaqus

- SolidWorks Simulation

- Autodesk Fusion 360

- COMSOL Multiphysics

- Siemens NX

Each tool has strengths in different areas. Some are great for mechanical parts, others are better for heat or fluid flow analysis.

Challenges in FEA

While FEA is powerful, it also has challenges:

- It depends on accurate input: Wrong material data or load values can lead to wrong results.

- It needs expertise: Setting up simulations properly takes skill and training.

- Computational cost: High-quality models with fine meshes can take hours or days to process.

- Too many assumptions: FEA can’t replace real-world testing entirely. Some things, like unexpected material defects or poor manufacturing, can’t be simulated.

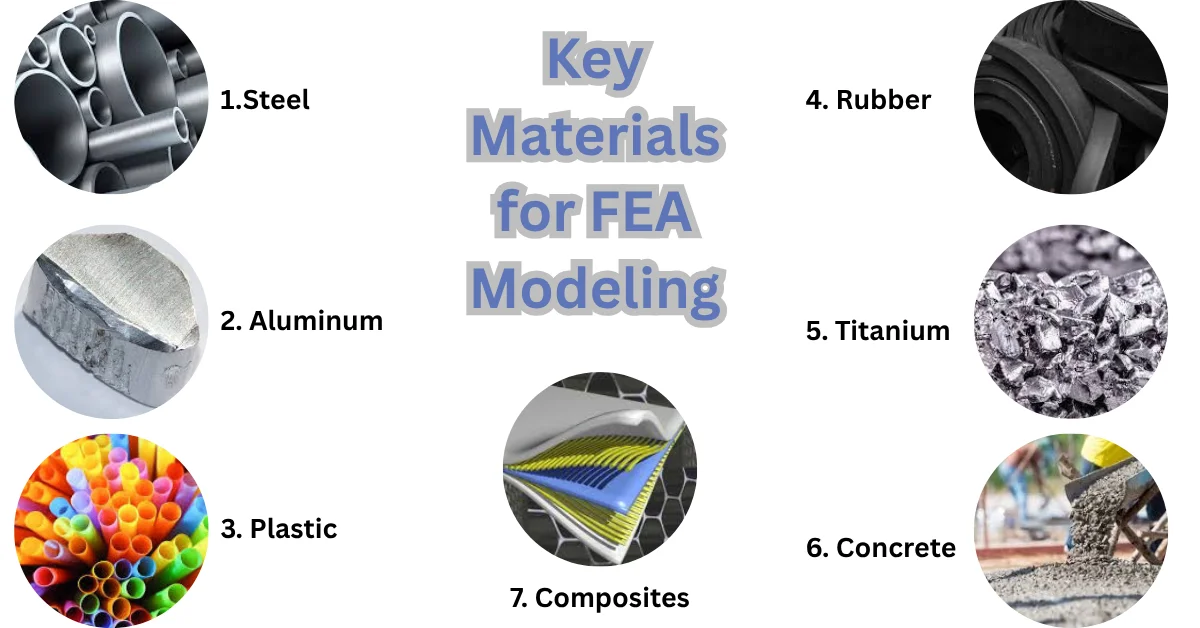

Common Materials Used in FEA

The choice of material matters a lot in FEA. Here are some commonly used materials:

- Steel

- Aluminum

- Plastic

- Rubber

- Titanium

- Concrete

- Composites

Each material has properties like elasticity, strength, and heat resistance. These properties must be fed into the software for accurate simulation.

Difference Between FEA and FEM

While often used interchangeably, FEM (Finite Element Method) is the mathematical theory behind breaking complex problems into smaller parts, while FEA (Finite Element Analysis) is the practical use of that theory through software to simulate real-world conditions. Simply put, FEM is the method, and FEA is the application of that method in engineering analysis.

Future Outlook

The field of Finite Element Analysis is evolving rapidly becoming more efficient, intelligent, and widely available. With the help of AI and machine learning, FEA tools can now optimize designs and predict issues more efficiently. Cloud computing allows engineers to run complex simulations without high-end hardware, making FEA available anywhere. Automation is streamlining preparatory tasks such as meshing and defining boundary conditions, significantly reducing the time and effort involved. Additionally, the rise of real-time simulations is providing immediate feedback on design modifications. As these technologies advance, FEA will become available to smaller companies and students, making powerful simulation tools more widely usable than ever before.

Conclusion

Finite Element Analysis has become a vital component of contemporary engineering, enabling the development of safer, more efficient, and economically optimized designs. By breaking down complex structures into manageable elements, FEA provides detailed insights into how objects will perform under various conditions, leading to better products and innovations across industries.