Internal threads refer to the spiral grooves cut on the inner surface of a hole to allow mating with external threads on bolts, screws, or other fasteners. High-quality internal threading enables secure joining of mechanical components.

While various methods exist for generating precision female threads, tapping remains the most prevalent production technique. Tapping involves a rotating cutting tool called a tap, which carves out the specific thread form profile as it feeds into a pre-drilled hole. Proper tap geometry, optimized feed rates, and lubrication allow factories and machine shops to produce internal threads to meet their functional tolerances and production volumes.

Most applications rely on a combination of precision machine tools matched with application-specific cutting materials and parameters.

Primary materials used for internal thread production:

Hand tapping manually cuts internal threads using a rotating tool. Operators apply axial pressure and torque to the hand tap inserted in a sized hole to form threads in the hole’s walls gradually. Hand taps come in various sizes, materials, and geometries to create basic threads in low-hardness metals. While versatile and accessible, hand tapping lacks automation and suits low-volume threading applications.

Machine tapping efficiently produces threads using power-driven taps mounted in precision equipment like CNC machining centers. The programmed equipment rotates the tap and controls axial loads and feed rates for accuracy and repeatability. Various machine taps also feature optimized geometries and coatings to withstand high-speed machining of tough alloys. Machine tapping enables medium to high production volumes along with threading challenging materials.

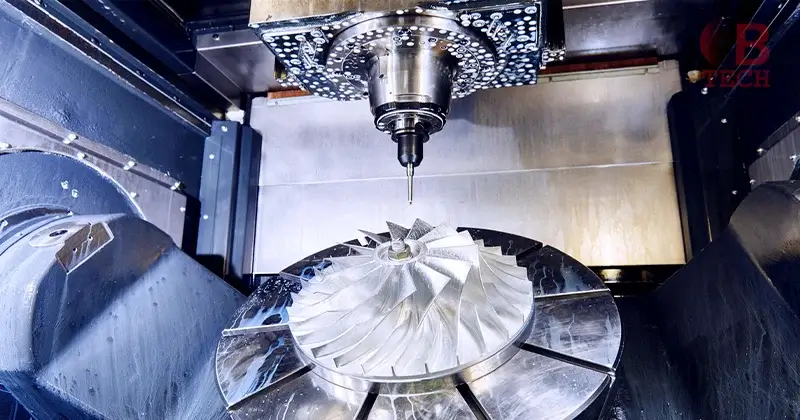

Thread milling utilizes special cutters with sophisticated geometry, rotating to generate the desired helical thread form. Multi-axis CNC programs the complex toolpaths, enabling thread mills to deliver internal and external threads. The method works for large diameters and suits one-off prototype parts. However, thread mills have somewhat higher associated tooling costs compared to taps.

Lathes, popular for precision turning operations, can also cut internal threads using single-point or indexable cutting tools. The machine rotates the workpiece at a set speed while precisely feeding the cutter to cut the thread grooves. Companies often apply this method to very large diameter holes, such as those found in some pipeline fittings or pressure vessels. It allows good control of thread accuracy but has limited productivity compared to tapping or thread milling.

Tapping inserts constitute an important material for quickly producing consistent internal threads on CNC equipment. The indexable inserts consist of replaceable, geometrically-ground cutting tips brazed or clamped to a reusable steel shank. Their geometries and coatings are engineered specifically for challenging materials or high-speed tapping. When flank wear dims cut quality, the disposable insert gets replaced while reusing the tool body. This makes tapping inserts extremely cost-efficient for large production runs.

FAQs

How are internal threads made in pipes?

Internal threads in pipes are commonly produced with the help of pipe threading taps. A tapping machine or lathe attachment holds a specially designed pipe tap. As the machine rotates the pipe tap, it cuts into the inner diameter of the pipe to form the internal thread profile. Proper selection of taps along with coolants ensures quality threaded connections in piping.

What tool is used for repairing a damaged internal thread?

A thread file, also known as a thread chaser, is used for repairing damaged internal threads. Thread files have cutting teeth and are available in different thread pitches and diameters. The thread file is inserted into the damaged thread and rotated to reshape and sharpen the thread profile. This restores the internal thread accuracy to assemble a mating part properly.

How are internal threads measured?

There are a few techniques for measuring internal threads. Air and ring gauges allow quick go/no-go assessment of fit with mating parts. More detailed evaluation involves using internal thread micrometers. These micrometers have threaded anvils that mesh with the threads for direct dimensional measurement. Other advanced methods include optical comparators to enlarge and inspect profiles or CMMs to map threads in high-resolution 3D.

Conclusion

Internal thread generation requires proper technique, tooling selection, and machining parameters to meet application requirements. Tapping remains the most versatile and adopted method, with hand taps for low-volume jobs and high-productivity machine taps for the production threading of even complex alloys.

While thread mills and lathe cutting allow flexibility, tapping inserts enable cost-efficient mass production. Optimized taps in terms of accuracy, tool life, consistency, and economy, therefore, constitute a primary material for internal threading across industrial contexts.

With increasing precision needs and material performance demands, research and innovation of taps and automated processes continue advancing manufacturers’ capabilities to produce robust internal threads matching component specifications.