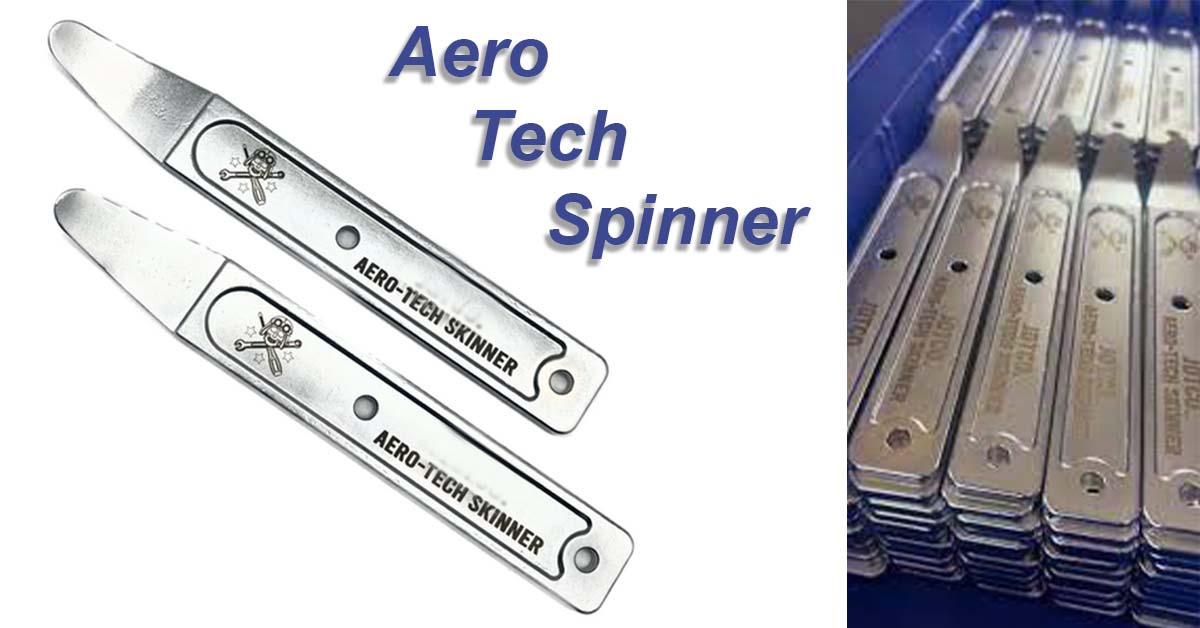

The aerospace industry is continually evolving, demanding cutting-edge technologies that enhance efficiency and precision. One such groundbreaking tool making waves in the industry is the Aero Tech Skinner. This innovative device has captured the attention of aerospace professionals worldwide, revolutionizing the way composite materials are cut.

In this article, we will delve into the details of the Aero Tech Skinner and explore its impact on the aerospace sector.

Introduction to the Aero Tech Skinner

The Aero Tech Skinner is an advanced cutting tool designed to handle a variety of composite materials used extensively in the aerospace domain.

It is a result of years of research and development, aiming to address the challenges faced by traditional cutting methods in this industry. With its state-of-the-art technology and unparalleled precision, the Skinner has quickly become a go-to solution for aerospace manufacturers seeking enhanced productivity and quality.

Key Features and Specifications

The Aero Tech Skinner boasts an array of cutting-edge features, allowing it to stand out from its competitors. Some of its notable attributes include:

- Multi-Material Capability: The Skinner can seamlessly cut through a wide range of composite materials, including carbon fiber, fiberglass and Kevlar. This versatility eliminates the need for multiple cutting tools, streamlining the manufacturing process.

- Dynamic Cutting Angles: Equipped with adjustable cutting angles, the Skinner ensures precision cuts even in complex shapes and curves. This adaptability significantly reduces material wastage and improves overall productivity.

- Automated Cutting Patterns: The device comes with an intuitive user interface that allows operators to program custom cutting patterns. This automation minimizes human error and enables the replication of precise cuts consistently.

- Real-time Monitoring: Integrated sensors provide real-time feedback during the cutting process. Operators can monitor factors like temperature, pressure, and blade wear, ensuring optimal performance and preventing potential issues.

- Enhanced Safety Measures: The Skinner prioritizes operator safety with features like blade guards, emergency stop buttons and safety interlocks. This focus on safety reduces workplace accidents and enhances overall efficiency.

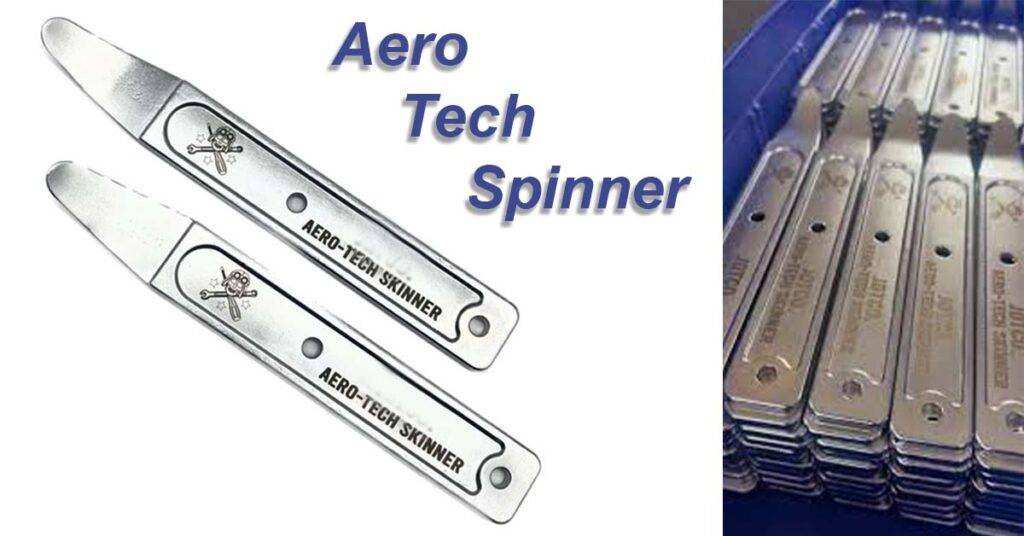

- Portability & Ergonomics: Despite its advanced capabilities, the Skinner maintains a compact design, ensuring ease of movement and operation. Its ergonomic handle and lightweight build contribute to the operator’s comfort during extended use.

Advantages of Using the Aero Tech Skinner

The Aero Tech Skinner offers numerous advantages over traditional cutting methods, making it a game-changer in the aerospace industry:

- Time Efficiency: With its automated cutting patterns and dynamic angles, the Skinner significantly reduces cutting time, accelerating the manufacturing process and shortening lead times.

- Cost Savings: The precise cutting capabilities of the Skinner minimize material wastage, leading to cost savings in raw materials. Additionally, its multi-material capability eliminates the need for multiple specialized tools.

- Improved Quality: The Skinner’s high precision ensures consistent and accurate cuts, resulting in superior-quality composite components. This, in turn, enhances the overall performance and safety of aerospace products.

- Increased Productivity: By streamlining the cutting process and reducing the reliance on manual labor, the Skinner boosts overall productivity, allowing manufacturers to meet increasing demands efficiently.

- Adaptability to Complex Designs: Aerospace products often feature intricate designs that demand precision cutting. The Skinner’s ability to handle complex shapes and curves makes it indispensable for cutting composite materials in such applications.

Applications in the Aerospace Industry

The Aero Tech Skinner finds applications in various areas within the aerospace industry, including:

- Aircraft Manufacturing: The Skinner plays a pivotal role in fabricating structural components, interior elements, and aerodynamic surfaces for modern aircraft.

- Spacecraft Construction: Its ability to handle diverse materials makes the Skinner an essential tool in crafting spacecraft components, satellites and other space-bound structures.

- Rotorcraft Production: In the production of helicopters and other rotorcraft, the Skinner ensures the precision cutting of rotor blades and composite frames.

- Unmanned Aerial Vehicles (UAVs): UAVs are becoming increasingly important in the aerospace sector, the Skinner aids in creating lightweight and durable composite parts for these devices.

Conclusion

The Aero Tech Skinner has undoubtedly made a significant impact on the aerospace industry by revolutionizing the way composite materials are cut. Its advanced features, precision cutting abilities and time-saving automation make it a valuable asset for aerospace manufacturers aiming to stay competitive in a rapidly evolving market.

As technology continues to progress, we can expect the Aero Tech Skinner to play an even more prominent role in shaping the future of aerospace manufacturing.